1/14/26

Your Custom Styli and Why the Material Makeup Matters

Across industries, the conditions and requirements placed on measurement equipment are far from uniform. Whether navigating tight timelines or inspecting sensitive components, your tools must adapt to demanding environments and materials.

The stylus you choose can influence everything from productivity to maintenance schedules, highlighting why the material makeup matters for your custom styli. As the landscape of manufacturing continues to evolve, knowing what your stylus is made of—and why—becomes a critical factor in both the reliability of your measurements and the long-term efficiency of your operations.

Why Styli Matter in Manufacturing

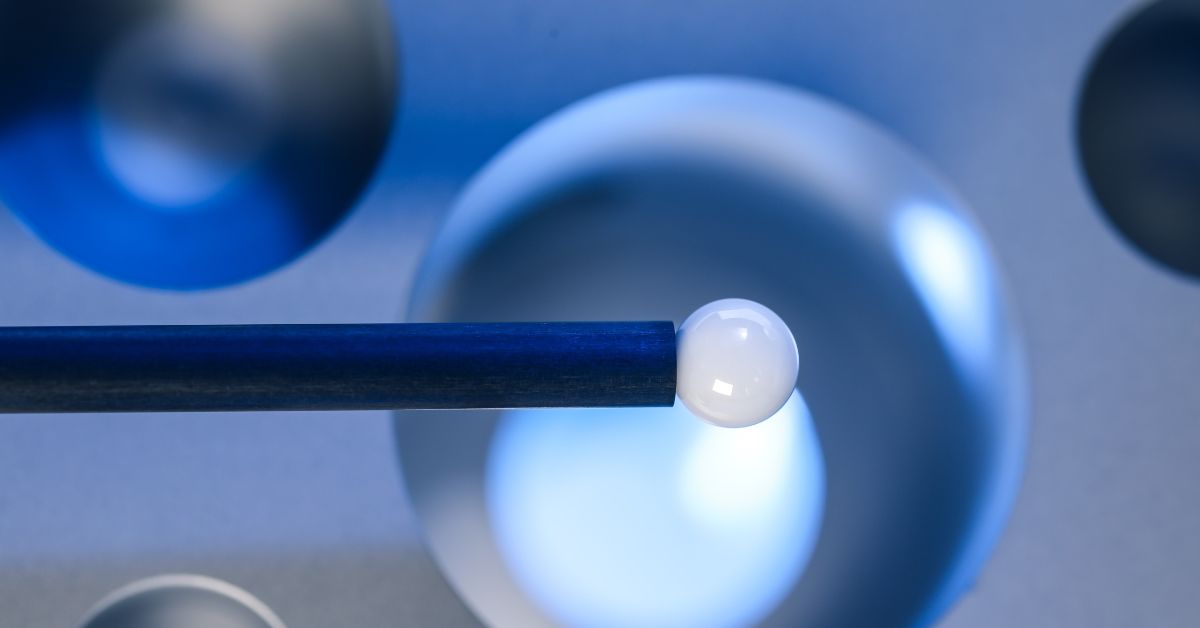

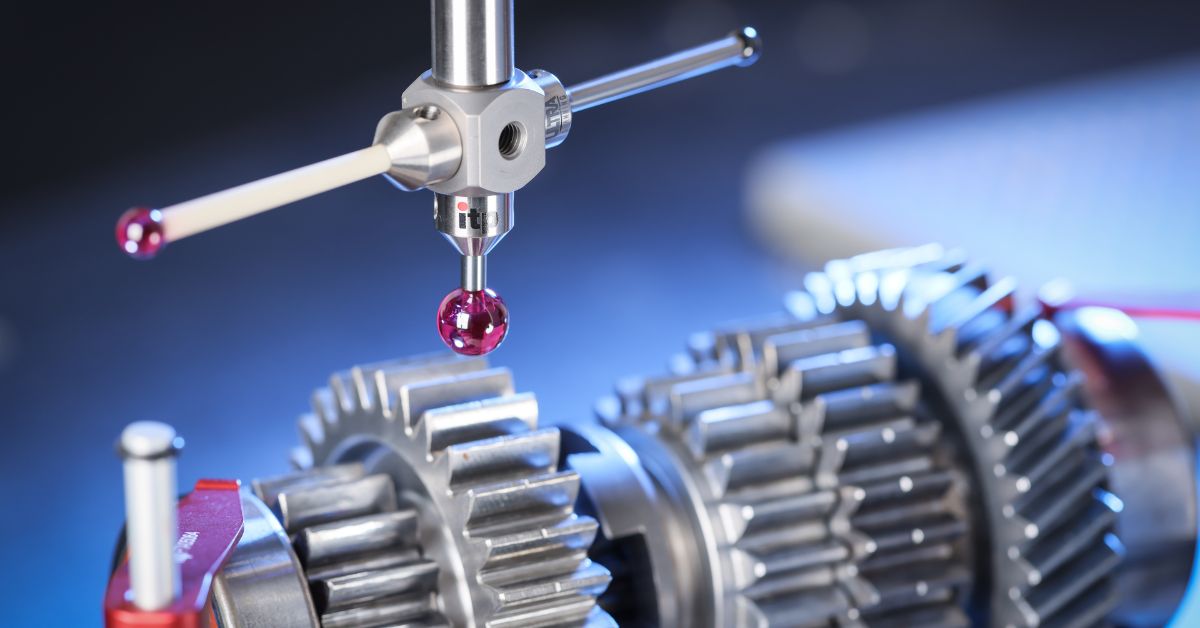

Styli are the sensory fingertips of your measurement equipment. They directly interact with the part you’re inspecting to gather raw data that determines whether a component meets its design specifications. A stylus's primary function is to touch the surface of a workpiece with a high degree of accuracy and transmit that positional information back to the measuring machine's sensor.

The slightest inaccuracy at this point of contact can be magnified, leading to incorrect measurements. This could result in perfectly good parts being rejected or, conversely, faulty parts being approved. In high-stakes industries, such errors can have major consequences, affecting safety, performance, and cost. Therefore, the integrity of the stylus (its shape, size, and material) is directly linked to the integrity of the entire quality control process.

The Science of Material Makeup

Selecting the material of a stylus is based on a range of physical properties that dictate its performance under specific conditions. An ideal stylus material should be exceptionally hard to resist deformation. It should also be lightweight to minimize inertia, which can cause measurement errors, especially at high scanning speeds.

Additionally, thermal stability is a key factor. Materials that expand or contract significantly with temperature changes can introduce variability into measurements. The environment in which the measurements take place, including the metrology and monitoring solutions, will influence the choice of material.

Common Stylus Materials and Their Applications

Every material has its own advantages and is therefore suitable for specific applications. Selecting the correct stylus material is a foundational step in ensuring measurement precision.

Ruby Styli

Ruby is the most common material for stylus tips due to its excellent combination of properties. It is extremely hard and smooth. Ruby styli are a versatile, general-purpose choice suitable for measuring most common materials like steel and brass. However, ruby is not recommended for scanning aluminum surfaces, as a phenomenon known as "adhesive wear" can occur, in which aluminum particles accumulate on the stylus tip and compromise consistency.

Zirconia Styli

Zirconia offers a surface that is tougher and more resistant to surface degradation than ruby. It is particularly effective for abrasive scanning of cast iron parts. Its unique surface properties reduce friction and the risk of scratching the component. As a result, it is a reliable choice for demanding inspection routines on rough surfaces.

Silicon Nitride Styli

With a hardness comparable to that of ruby, silicon nitride exhibits exceptional resistance to adhesive wear. This makes it the ideal choice for scanning aluminum and other soft, nonferrous metals. Its smooth, nonporous surface prevents material transfer from the workpiece to the stylus tip, maintaining measurement integrity over long scanning sessions.

Tungsten Carbide Styli

Known for its rigidity and high density, tungsten carbide is often used for the stems of styli rather than the tips. Its stiffness is beneficial for creating long, slender styli that resist bending. This material is suitable for applications requiring a robust shaft to support a small tip or to reach deep features within a part.

Diamond-Coated Styli

For the most extreme applications, diamond-coated styli offer the highest level of hardness and resistance to deterioration. They are exceptionally durable and can withstand continuous scanning on very hard or abrasive materials, such as ceramics and composites. The diamond coating provides a long service life and maintains a precise spherical form far longer than other materials.

Custom Styli: Tailoring to Your Industry Needs

While a vast catalog of standard styli exists, off-the-shelf solutions are not always sufficient. Many manufacturing applications involve unique geometries or specific material challenges that require a tailored approach. Custom styli are designed to solve these particular measurement problems.

For example, a complex aerospace component might have deep, narrow bores that a standard stylus cannot access without flexing or colliding with the part. In this case, a custom stylus with a specific length, a stepped-diameter stem, or a unique tip configuration can be engineered.

Similarly, inspecting delicate electronic components may require an ultra-lightweight stylus with a minuscule tip to avoid damaging the part while capturing fine details. Customization allows for the optimization of stiffness and weight to meet the precise demands of the task.

Accessories and Replacement Solutions

The measurement ecosystem extends beyond the stylus itself. A comprehensive range of accessories is necessary to support and enhance probing systems. This includes extensions to increase reach, adapters to connect different components, and tool changers to automate switching between styli during an inspection cycle. Having access to high-quality, compatible accessories is critical for building a flexible and efficient measurement setup.

Furthermore, styli are consumable items that wear over time. Proactive replacement is essential for maintaining correctness. Partnering with a supplier that offers a wide inventory of replacement styli and accessories ensures that you can quickly and easily acquire the components you need to minimize downtime and keep your quality control processes running smoothly.

Choosing the Right Supplier

Selecting the right supplier for your stylus and accessories is as important as choosing the right material. A knowledgeable supplier acts as a partner, offering expertise and guidance to help you navigate the complexities of measurement technology. They should have a deep understanding of CMMs, machine tools, and the specific challenges of various industries.

Look for a supplier with a broad inventory of in-stock items to ensure quick delivery and prevent delays in your operations. A strong partner will also offer robust customer support and have the capability to design and deliver custom solutions for your most difficult measurement tasks.

The right partner stands apart because they recognize why the material makeup matters for your custom styli, helping you find confidence in your measurement results. itpstyli is your trusted partner in metrology solutions. Contact us for comprehensive support and a vast selection of styli and accessories.