1/14/26

Maximizing Tool Life: Care Tips for Straight Styli

Your entire manufacturing workflow depends on measurement data you can stand behind, and you rely on your CMM to give you an honest read on every part that moves through your process. What is often overlooked is that this accuracy starts at the very tip of the probe, where a straight stylus first contacts the part.

Small changes in condition can shift the story your inspection system tells you. That’s why we’re focusing on practical care tips to maximize tool life for straight styli. When you understand how styli actually wear out and how small daily habits protect them, you safeguard the validity of your measurements and keep your inspection routine running smoothly.

Choose the Right Stylus for the Application

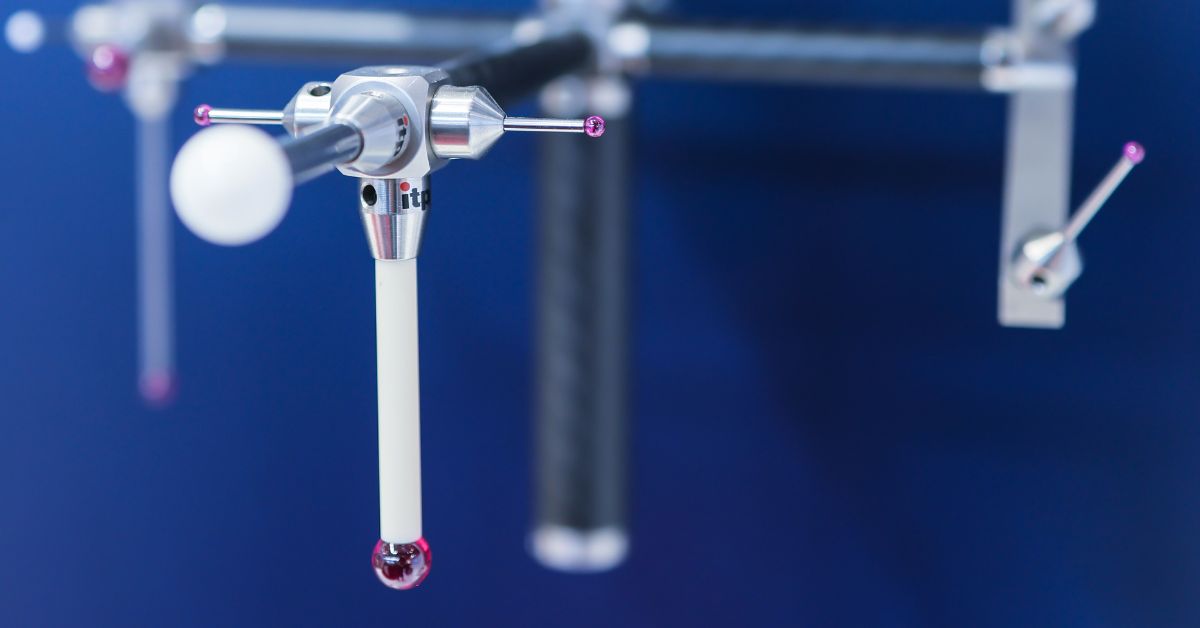

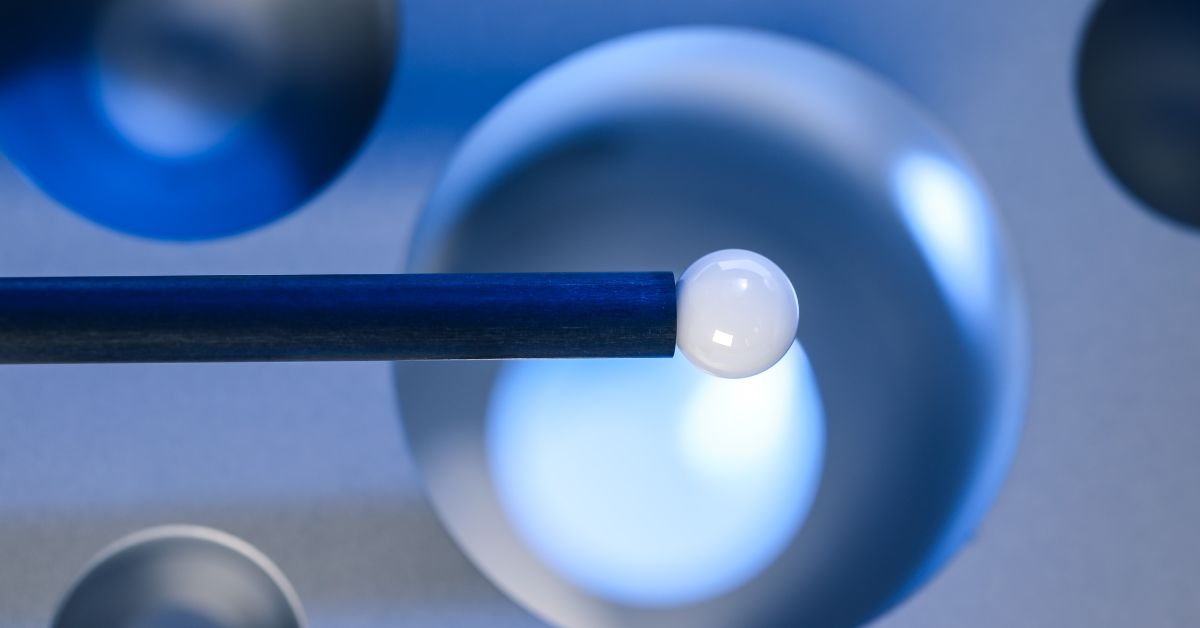

Selecting a stylus requires more than matching size and shape to the measurement point. The material of the stylus ball and stem plays a central role in performance and longevity.

For example, a ruby ball stylus provides excellent wear resistance against most machined metal and plastic surfaces. However, if you routinely measure high-hardness materials or work in abrasive environments, materials such as silicon nitride or diamond-coating may withstand wear and contamination better.

Similarly, stainless steel stems are best in standard settings, but applications requiring minimal thermal expansion or increased rigidity often benefit from ceramic or tungsten carbide constructions. Weigh the physical demands of your process before choosing a stylus. Thoughtful selection pays off over time with longer-lasting components and more consistent measurement results.

Handle and Install Styli With Precision

Styli are precision components that must be handled with care, as even minor contamination can impact their performance. Always use lint-free gloves and avoid direct skin contact. Handling the stylus only by its base reduces the risk of oils reaching sensitive areas.

Installation requires attention to torque. Over-tightening can deform threads, while under-tightening can cause instability and a risk of misalignment. Use a proper torque wrench or specified tool whenever possible, and follow the manufacturer's recommendations.

Keep Styli Clean To Prevent Measurement Drift

Production environments continuously introduce contaminants such as dust or residues from parts and tooling. These substances can easily accumulate on the stylus ball, altering its exact diameter and contributing to errors across a series of measurements. Cleaning your stylus at regular intervals helps preserve correctness and minimizes drift.

Gentle cleaning is essential. Rely on suitable solvents compatible with stylus materials, and choose lint-free cloths or wipes. Never use harsh abrasives, which can scratch the surface and reduce operational life. Attention to cleanliness supports your shop’s reputation for quality.

Inspect Styli Regularly for Wear and Damage

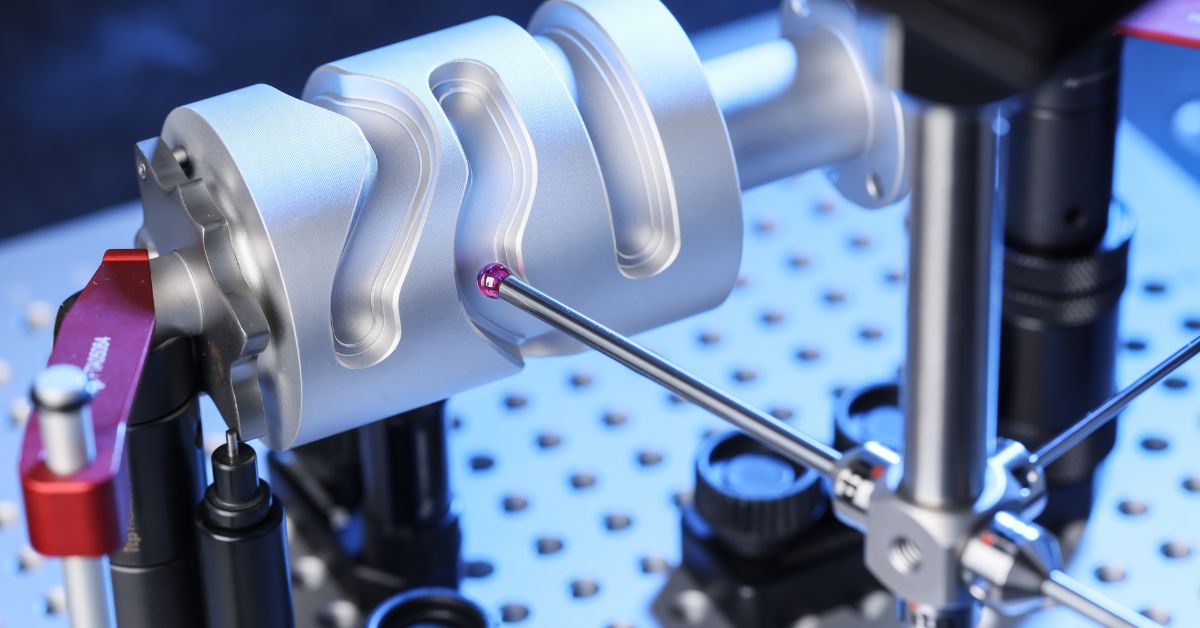

Consistent inspection practices let you catch problems before they affect your output. Inspect the stylus under magnification, watching carefully for flat spots, scratches, or embedded particles. Even a high-quality stylus can develop micro-defects through regular contact with hard surfaces.

Going beyond visual checks, review calibration and measurement data over time. Outliers in the data may signal deteriorating stylus integrity, making now the time to intervene. Early identification prevents nonconforming parts and maintains customer trust.

Protect Styli From Excessive Force and Side-Loading

CMM programs must be carefully designed to avoid accidents during probing and movement. Collisions with clamps or components can cause catastrophic damage or subtle distortions to the stylus. Reduce feed rates when approaching a part, and avoid rapid moves in tight spaces. Slow, deliberate movement minimizes risk and extends stylus lifespan.

Side-loading is another avoidable danger. Only the stylus ball should make contact during measurement. Any sideways force on the stem can bend or fracture it, reducing exactness. Validate CMM paths before automated cycles, making sure the ball (not the stem) is your only contact surface.

Maintain a Stable, Clean Measurement Environment

Even robust equipment can suffer from temperature swings and humidity. Place your CMM and accessories in a controlled environment when possible. Sudden changes in temperature affect the dimensional stability of both the stylus and the workpiece, which produces inaccuracies.

Air quality matters as well. Install HEPA or appropriate filtration in your inspection area, and regularly wipe down your surfaces and equipment. A pristine, climate-controlled space prevents premature wear and supports predictable, reliable results day after day.

Keep Accessories in Top Condition

The performance of your straight stylus depends on the condition of every connected accessory. Damaged threads, dirty adapters, or worn extensions can all introduce unwanted movement or instability. Take the time to clean and double-check these parts when swapping out components or during routine maintenance.

Proper storage for these accessories is key. Use designated holders or foam-lined drawers to avoid accidental impacts and dust accumulation. Organized storage extends the working life of components and makes it easier to quickly locate the right accessory when you need it.

Recalibrate After Stylus Changes or Adjustments

Changing a stylus or any critical component affects your reference geometry and warrants immediate recalibration. Running a fresh calibration after every change maintains true probe coordinates and measurement integrity. This routine practice quickly compensates for even tiny variations in stylus length or orientation.

Occasionally, review your calibration protocols and the health of your equipment. As machines and accessories age, slight shifts may occur. Detecting these changes early minimizes time lost to troubleshooting or rework and helps maintain confidence in your process.

Partner With a Trusted Stylus Supplier

Sourcing styli and accessories from a reputable supplier ensures you receive parts that meet or exceed industry manufacturing standards. Partnering with itpstyli, for example, demonstrates a commitment to quality, support, and performance. Trustworthy suppliers offer technical guidance that helps you select products tailored to your unique needs and support you if challenges arise.

A dependable supplier provides traceability, so you’re sure about the origins of every critical replacement part. Their expertise extends your team’s capability, and ongoing access to a broad range of high-quality solutions allows you to respond quickly to new jobs or evolving customer demands. Confidence in your supplier directly reflects on your reputation.

Consistent attention to stylus care demonstrates a professional’s investment in reliable measurement and precision-driven outcomes. The difference lies in the commitment to equipment upkeep and the willingness to adopt care tips to maximize the tool life of straight styli. With the right mindset and supportive resources, you’re equipped to meet evolving expectations and deliver quality with every measurement.